Choosing the perfect handrail for your home or business means sifting through lots of options. From various profiles to the choice of components, it’s essential to select materials that will allow your handrail to stand the test of time, maintaining its function and beauty. Handrails come in a variety of materials, including aluminum, wrought iron and wood. Wood is a commonly used material but presents many issues not found in alternative handrail materials.

What if we told you that you could have the elegance and sophistication of a wood handrail without the pitfalls? This article will address the common short- and long-term issues with wood stair handrails before introducing you to an innovative, long-lasting and low-maintenance alternative.

1. Often Made of Cheap Materials

1. Often Made of Cheap Materials

Traditional wood handrails are often made of softer woods like pine to cut down on cost. Unfortunately, this also cuts down on strength and durability. Cheaper wood materials are prone to denting and scratching, requiring additional effort and maintenance to keep them looking nice over time.

2. High Warping Probability

Wood is a hygroscopic material, meaning that it is altered by the amount of moisture in and around it. When it loses moisture, it shrinks. When it gains moisture, it swells. Therefore, even indoors, dry or humid air can affect wood handrails, causing them to swell, shrink and warp over time.

Once a handrail is warped, fixing it is very difficult, if not impossible. This tendency to warp means that the majority of wood handrails are not suited for use as exterior wood handrails, though pressure-treated handrails can be used as deck railings.

3. Have to Cut/Miter

A continuous handrail is necessary for safety and stability and to comply with ADA standards and commercial and residential building codes. Special joints are needed to make a wood handrail continuous. You may also need to cut 45-degree angles and match the cuts to turn a 90-degree corner.

4. Reliable, Elegant Hardwoods are Expensive

If you choose to use wood for a handrail, there are more reliable options, such as maple or oak. These hardwoods are more expensive than the softer woods, though they are more durable. Another factor to consider when choosing hardwood is the look they create, which is desirable for a particular design aesthetic – namely, traditional.

Hardwoods generally don’t provide much in the way of structural improvements over softwoods. In addition, because they are primarily found in a pinch grip profile, they usually lack adequate handhold requirements and do not meet ADA guidelines or building codes.

5. Have to Drill in Brackets

5. Have to Drill in Brackets

One of the most pressing concerns for wood handrails is the installation process. Brackets and hardware must be attached directly to the wood handrail, presenting several challenges. First, the screws themselves have to be reasonably short, so they don’t puncture the top of the handrail. Because the screws are short, the brackets tend to loosen over time, creating a handrail that doesn’t provide a safe and secure handhold for people using the stairs or ramp.

Another challenge for installation arises when measuring for bracket placement. Because the brackets are screwed into the handrail, measuring the studs’ locations and lining up the brackets on the handrail must be precise. If you mismeasure, the brackets must be removed and repositioned, leaving holes in the handrail. These holes are not only unattractive but can cause splinters and damage the integrity of the wood handrail.

6. Requires Sanding, Sealing, and Staining

Many wood handrail options come unfinished. While this means that you can customize the stain to match existing woodwork or current design, it requires substantial work. To stain a wood handrail, you should first sand it to ensure there are no blemishes, which creates dust and mess. After sanding, staining requires a well-ventilated area and the possibility of multiple coats. Finally, the wood handrail should be sealed to help it maintain its appearance over time.

Even after all that work, a solid wood handrail runs the risk of warping, scratching or denting, leading to repairs or replacement down the road. Overall, this translates to more time and money spent.

Why Promenaid TrueWood™ Is Better Than Traditional Wood

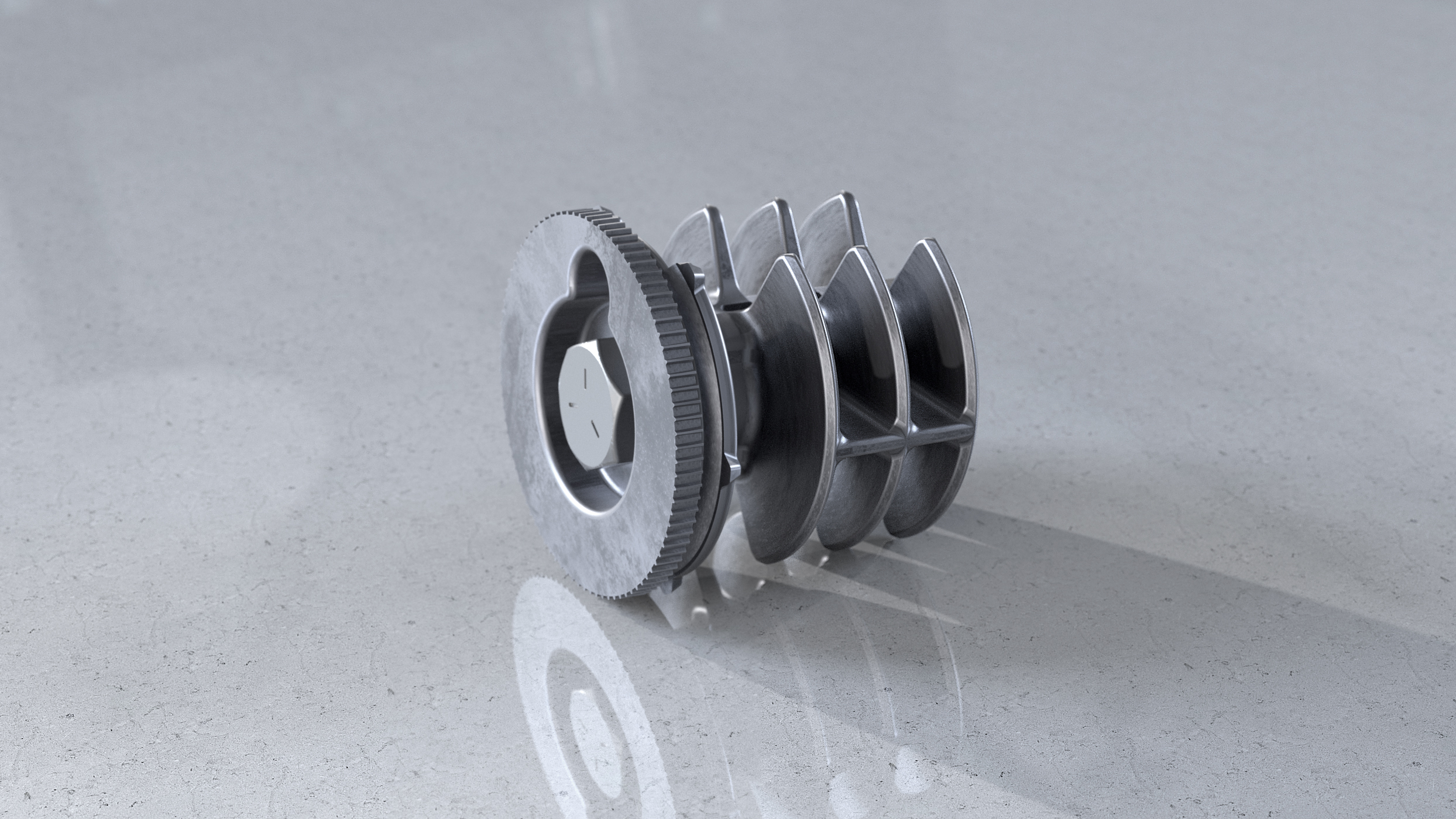

Luckily, there is a better alternative to wood handrails. Promenaid offers an innovative solution that uses the aesthetic of wood handrails without the maintenance, mess and upkeep of traditional wood handrails. Promenaid’s TrueWood™ handrails are far superior to traditional wood handrails in several ways. TrueWood™ handrails are created by manufacturing a thin layer of genuine red oak or black walnut wood that is then bonded to Promenaid’s aluminum handrail. This process creates a handrail that will never warp and is as hard and durable as aluminum with the traditional beauty of real wood.

Unlike traditional wood handrails, a TrueWood™ handrail has all the benefits of aluminum. These benefits include a greatly reduced risk of denting, cracking or warping while maintaining the beauty of wood. In addition, this genuine wood handrail uses 50 times less than the amount of wood that a traditional wood handrail uses, making it a more sustainable option. In fact, our alternative wood handrails are manufactured in North America using sustainable materials.

Unlike traditional wood handrails, a TrueWood™ handrail has all the benefits of aluminum. These benefits include a greatly reduced risk of denting, cracking or warping while maintaining the beauty of wood. In addition, this genuine wood handrail uses 50 times less than the amount of wood that a traditional wood handrail uses, making it a more sustainable option. In fact, our alternative wood handrails are manufactured in North America using sustainable materials.

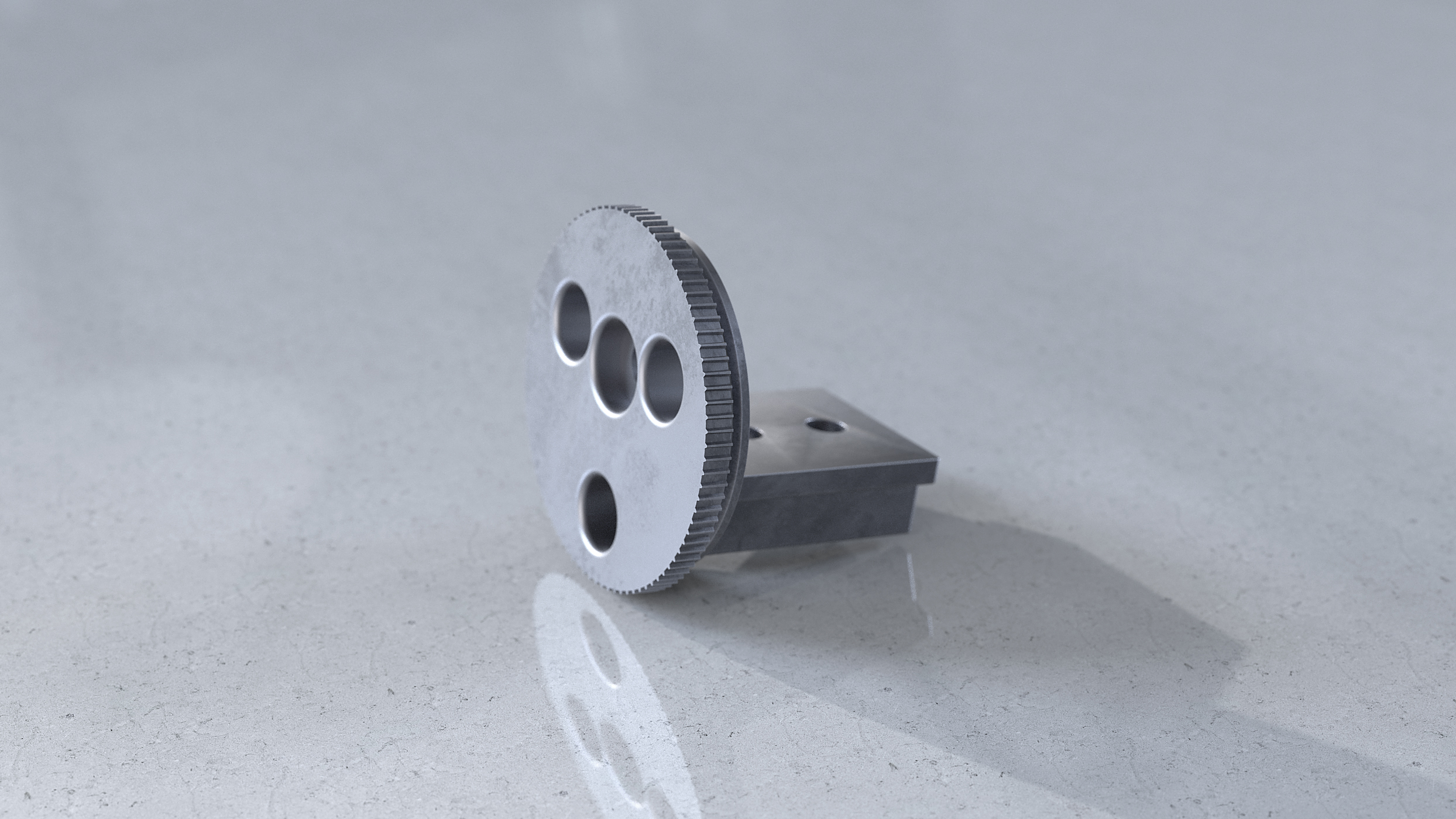

Another benefit of our TrueWood™ handrails is that installation is fast and easy as a result of our patented channel grip. This innovative channel allows for adjustable bends, clip-in brackets and lighting upgrades for your wood stair handrails. In addition, the channel means that measuring for bracket placement becomes substantially easier than if the brackets need to be screwed directly into the railing. If you mismeasure the bracket placement, you simply turn the twist-lock bracket 90 degrees and slide it to line up perfectly with the stud every time.

Promenaid’s TrueWood™ handrails can also be custom cut to whatever length you need, to the inch, in contrast to traditional wood handrails that come in pre-cut sections that must be cut to length. However, if you need to cut a TrueWood™ handrail on-site for installation, it can be cut with a standard miter saw as easily as cutting a 2-by-4 wood stud.

Like our Endura™ anodized aluminum handrails, our TrueWood™ handrails are ADA-compliant and meet the most stringent residential and commercial building code requirements.

We’ve created a series of educational training videos for your convenience to help you better understand the simplicity of Promenaid handrail installation. Additionally, we have a collection of documents and guides to help streamline the installation process. Finally, if you’re ever stuck, feel free to reach out to one of our experts for troubleshooting assistance.

Choosing our better, more durable alternative to traditional wood means cutting down on installation time and maintenance over the life of the handrails. With TrueWood™, you’ll no longer need to worry about warping, whether you install our handrails inside or outside. Beautiful and durable TrueWood™ handrails will meet your needs and look incredible doing it.

With several convenient purchase options, including kits and individual components, you’ll be on your way to the handrails of your dreams in no time. You can also use our search tool to locate a dealer near you. In some circumstances, our handrails can go from our warehouse to your job site in as little as 24 hours. Most orders placed before noon EST will be processed within 24-48 hours, and all shipments will be en route to you within two days of purchase.

Contact a team member at Promenaid today for more information on the best wood handrail solution for your space.