The construction industry, more than any other business niche, consistently encounters pressure to adapt and innovate in order to thrive. Architects, designers, and consumers are always looking for ways to create structures that go up faster, are more economically efficient, and meet loftier environmental standards.

Fortunately, the rapid adaptation of technology has answered the bell for these demands. The World of Concrete’s 2024 Innovative Product Awards highlighted some of the most exciting developments in the world of construction, exhibiting the myriad ways that new products and processes are improving the quality of our built environment. The following breakdown zeroes in on 8 of the most vanguard materials to receive recognition and analyzes the ways that they offer exciting solutions for the construction industry in 2024.

1. Tekpost™ with Slope Sync™ Technology by Promenaid

Promenaid’s Tekpost™ with Slope Sync™ can be used for a variety of purposes within commercial, residential, and industrial construction industries.

This new innovative product is the ultimate solution for installing vertical posts on sloped surfaces. Simply set the easy-to-read dial to the angle needed and secure the code-compliant post with a single bolt, eliminating the need for shimming, core drilling and grout drying delays.

Paired with high-quality handrail systems, these posts are suitable for both indoor and outdoor applications, adding a touch of elegance to any space. The modern look seamlessly integrates with any architectural style desired.

2. Select Joint Tape by Nox-Crete, Inc.

Nox-Crete’s Select Joint Tape is a specialized polyethylene tape for tilt-up construction, applied as a temporary saw-joint cover to reduce sacking and patching costs. With proper application, it can greatly reduce rubbing and patching of tilt wall panel surfaces.

The product was recognized as a leader in sustainable insulation among new construction materials. It prevents moisture, dust, and debris intrusion at saw-joint cuts, is submersion resistant for up to 48 hours, and resists UV degradation for up to 28 days. The tight seal effectively protects tilt-up panels from labor- and energy-intensive repair and leaves no residue on the casting slab upon removal.

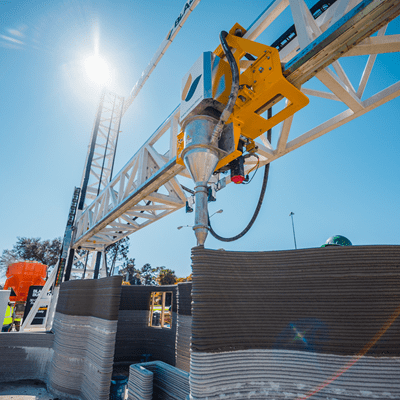

3. Planitop 3D Printing Mortar by MAPEI Corporation

MAPEI Corporation’s Planitop 3D Printing Mortar was recognized among new materials in construction for its disruptive innovation in concrete fabrication. This product is a fiber-reinforced cementitious mortar designed to be machine-applied using 3D printing processes for concrete. It is ideal for both interior and exterior applications and can be used in the creation of vertical, overhead, and horizontal concrete surfaces.

The proprietary blend of hydraulic binders, fiber, and well-graded aggregates ensures that this mortar adheres to the highest quality standards and meets ICC-ES AC509 requirements. It will set and support every concrete layer printed above it, helping save time, reduce material waste, and increase jobsite efficiency for every concrete project.

4. MaintainX: Mobile-First Maintenance and Asset Management by MaintainX

MaintainX’s robust digital platform earned a people’s choice winner as a top business and software technology for the concrete construction industry. It is a leading platform for digitizing workplace service requests and work orders, adding efficiency to maintenance and servicing to limit operational downtime.

Among the many features in the mobile software, it increases workplace productivity and compliance by making it easier to schedule, record, and monitor maintenance work. Its powerful AI workflows reduce administrative tasks, errors, and unexpected interruptions. It greatly assists project managers in knowing which assets are active, which assets are inactive, tracking time between operational failures, and getting assets back up and running as quickly as possible. It truly puts preventive maintenance on autopilot, reducing downtime for equipment with built-in work orders for routine servicing.

5. CaptureCrete™ by Carbon Limit

Carbon Limit’s CaptureCrete™ is at the vanguard of innovative building materials, winning an expert’s choice award for disruptive innovation through its carbon-capturing technology. CaptureCrete™ attracts carbon dioxide pollution from the surrounding atmosphere and stores it permanently at a deeper depth through a process known as carbonization. This provides an active and permanent carbon capture and storage solution, helping reduce the carbon footprint of construction projects by as much as 75%.

In addition to these benefits, CaptureCrete™ also scores highly in terms of durability. Lab tests reveal that CaptureCrete™ actually has increased compressive strength compared to standard concrete, as the carbonization process helps the material develop self-healing properties.

6. MARCOTTE Intelligent Feed by MARCOTTE

MARCOTTE’s Intelligent Feed is changing the way that concrete producers are leveraging AI capabilities. It is the world’s first AI-powered solution to optimize the concrete production process, driven by MARCOTTE’s Aurora AI technology.

Intelligent Feed was given an expert choice award for disruptive innovation in concrete production and delivery. It helps concrete producers address numerous challenges simultaneously, such as labor shortages and more stringent standards for sustainability. By using AI to address real-time production challenges that humans simply cannot account for, the software dynamically adjusts concrete production to guarantee optimal quality and consistency around the clock, regardless of the company’s existing production infrastructure. It is guaranteed to save the user money by optimizing material consumption, reducing equipment calibration times, and ensuring compliance with all contemporary environmental production standards.

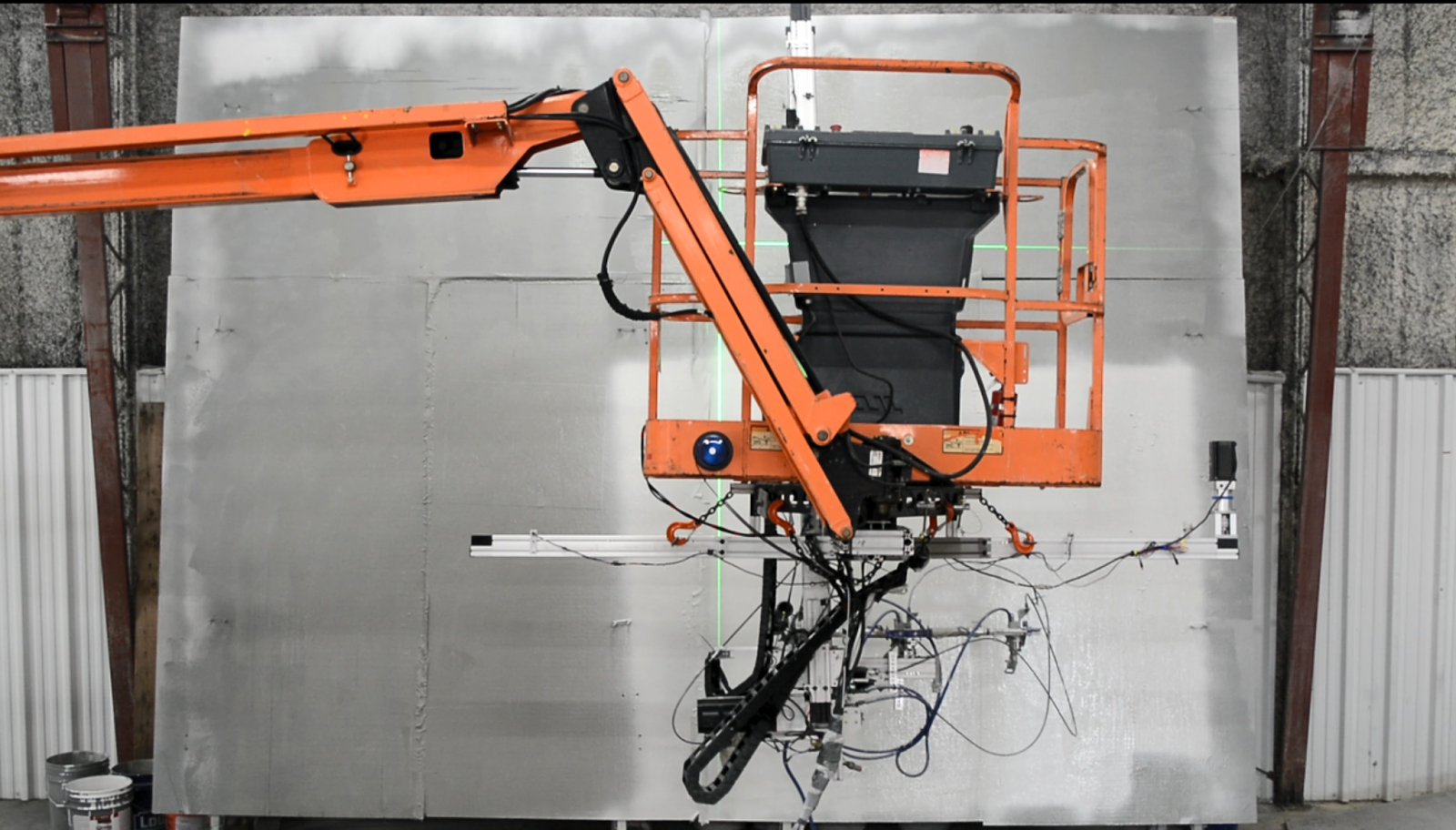

7. PaintJet Robotic Painting System by PaintJet

PaintJet’s Robotic Painting system is recognized as an industry leader among new building materials for its revolutionary methods of commercial painting. It uses robotics and advanced data to achieve elite precision in a wide range of applications.

By integrating technology and AI throughout the entire painting process, PaintJet is able to deliver superior quality, application efficiency, and improved asset protection. In addition, reductions in overspray and more accurate predictions of asset maintenance life cycle help large-scale projects to be completed faster and more affordably than average.

8. The Crack Stitch by Fortress

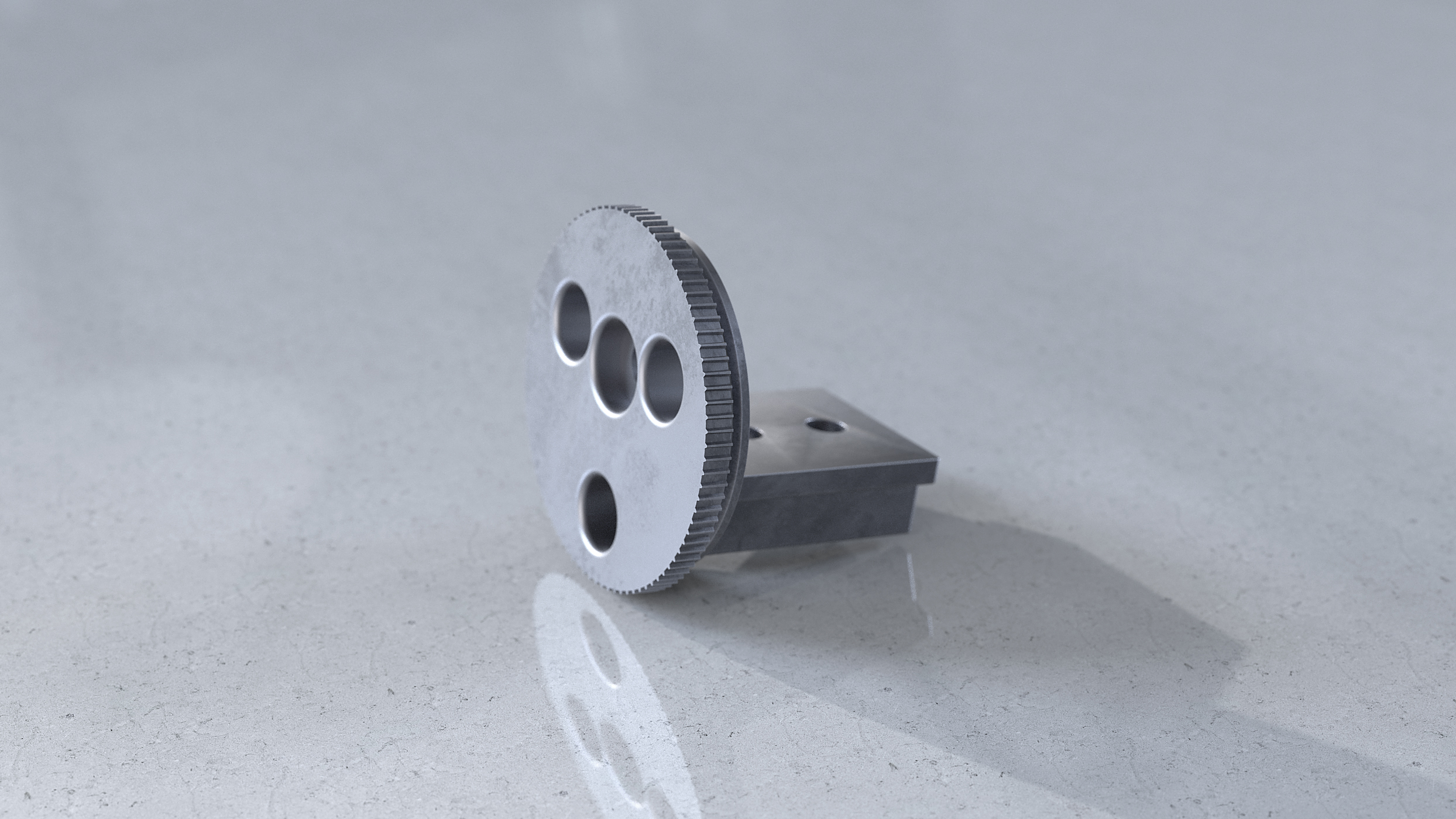

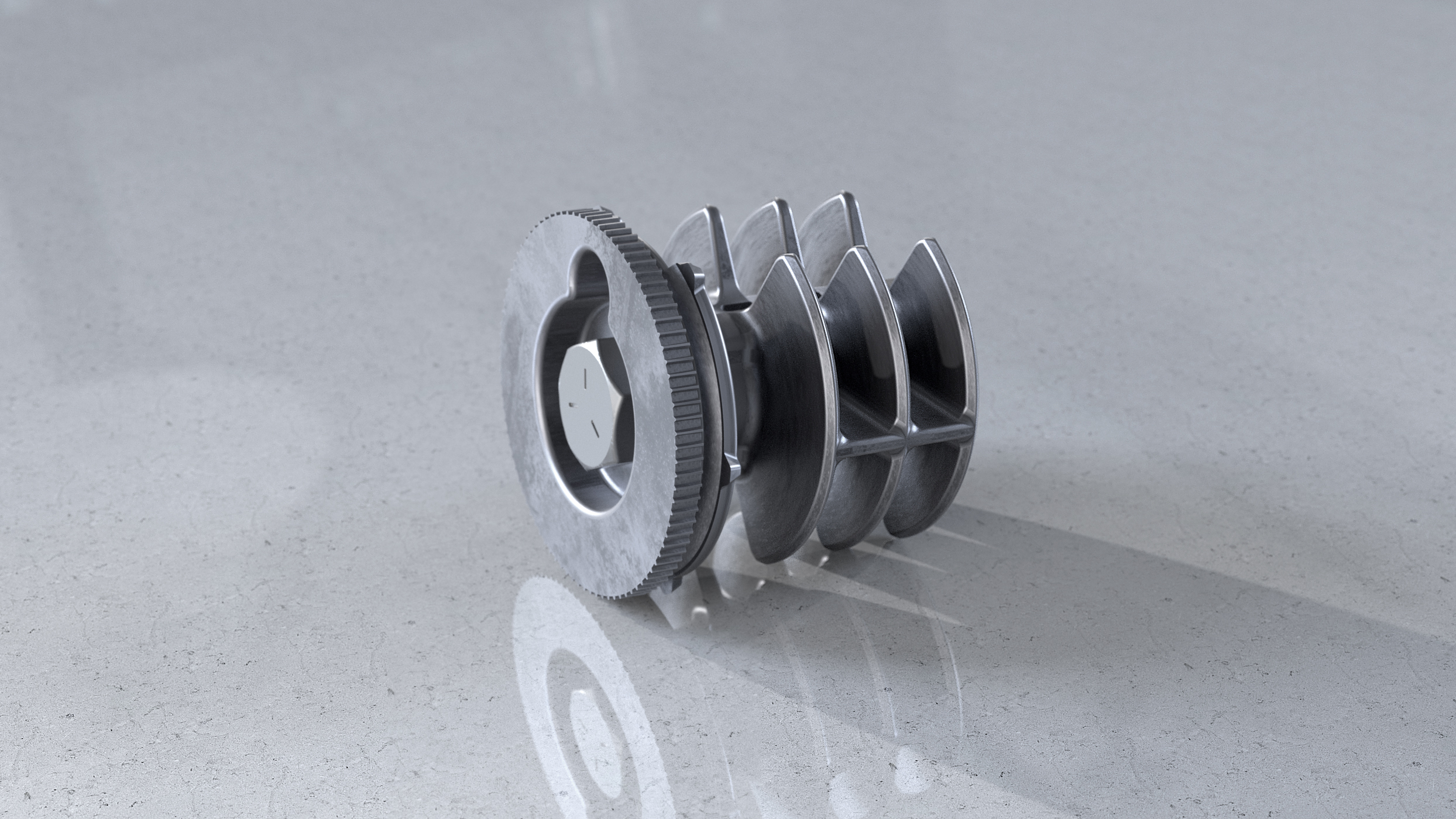

Fortress’ Crack Stitch won an expert’s choice award for sustainable innovation in the Repair & Demolition Tools, Materials, and Equipment category for its industry leading technology in repairing concrete cracks. It features Fortress’ patented ReGrid technology that uses a combination of carbon fiber and Kevlar to create an open grid “stitch” that creates a bond stronger than any other repair product on the market.

The Crack Stitch ensures that a crack will never reopen by inducing a process known as adhesive riveting. The pre-cured carbon fiber tows are cross threaded with Kevlar to create an open grid, through which epoxy, mortar, and other types of cementitious mixes can form rivets throughout the thread. These rivets create a mechanical bond that allows the carbon fiber to take on the stress placed on the concrete, creating a repair that is 4X stronger than the competition. The Crack Stitch has the added benefits of being non-corrosive and easy to install.

The Best of 2024: Innovative Construction Materials

Although the construction industry is constantly evolving, this list provides an exciting snapshot of the latest and greatest material technologies in the construction world. Expect continued improvement and refinement in the year to come as the industry aims to improve efficiency and quality of life across the globe.